km3 is parallel lay core might help improve the results. (less losses)

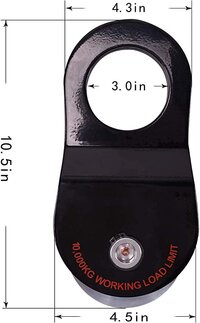

8:30 km3 in 5/8 cmi pulley 2.04/1.86 = 1.1

next two look like on polyester or nylon cover of soft shackle:

9:10 km3 amazon red ring 2.1/1.58 = 1.33

9:50 km3 beast x ring 2.24/1.78 = 1.26

11:00 km3 rigging shackle body U 2.08/1.30 = 1.6

note: 1.6 is about the same as rough tree bark

edit - bad memory - it's 2.6 not 1.6 apologies for that.

11:40 km3 DMM steel carabiner (dia?) 2.14/1.28 = 1.7

my data for comparison (tachyon rope):

W40 0.471 dia big steel biner 1/2 wrap tension ratio 1.86 mu 0.197

W41 0.375 dia half cylinder small blue Metolius biner 1/2 wrap tension ratio 2.07 mu 0.23

W42 big heavy yoke N-261 0.49" wide with edge rounds matching 1/4" diameters, flattish face, 1/2 wrap tension ratio 2.4 mu 0.28

12:52 CMI block you can predict the result:

cmi block (1+1/1.1.) x 2.04 = 3.9, meas 4.09 (?) settled?

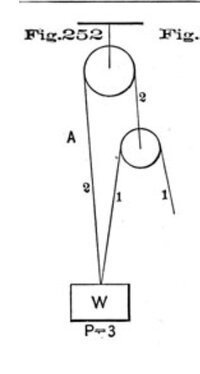

13:37 directly on shackle fiber, not on cover, red ring, ring spinning (1+1/TR) x 2.0 = 3.43

calc TR tension ratio = 1.4

meas TR was 1.33 this run did a bit worse.

I went through the backwards math to figure out Donzeli's block tension ratios.

14:16 beast x ring spinning on soft shackle cover (not directly on fibers)

(1+1/TR) x 2.04 = 3.8

calc TR tension ratio = 1.16 seems quite good. Maybe too good?

meas TR was 1.26. Something happened to get "too good" data. settled?

It would be worth trying different soft shackles i.e. your shackle(edit - ring!) on fibers, your shackle(edit - ring!) on cover, on slippery dyneema direct. Best to do the direct tension ratio first setup you used. Then that TR can be used to predict all your various configurations.

When I have doubt about a data set I try it twice. Catches the odd error and gives confidence.

Great finding a kindred nerd! Good stuff!

The whole concept of tension ratio came about because I used a whole bunch of points from the graph of tension vs time in my recording as I raised the tension and they all worked out to a constant ratio. The ratio reversed as I lowered the tension. Somewhat expected.