Note in Samson model, the player needed an equal and opposite against(so used other column)

and attacked the mighty target column of cos1(bearing massive weight properly of roof inline downward column)across at it's Achille's Heel of cos0 perpendicular to column as greatest leveraged angle. i stay with the Greco/Roman mythology imagery and 'simple' geometries of the time like simple kid stories as a fascination what Ancients tried to lend and the deep simple level to try to understand and pass it on at.

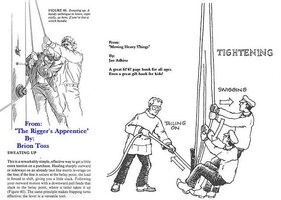

(note subtlety of swiggers leveraging, then also kinda quickly serving to snatch of tailerman downward too at right time)

in rope usage and heritage, tailerman /tender is very important in capstan cranking as well.

Mr. Ashley in ABoK gives sailor's verb of 'purchase' that see scant references to from others.

Usually we use 1 rope for leverage, and then capture a purchase thru the friction buffer quickly moving with 1 line for both operations.

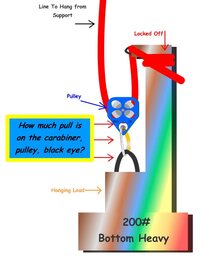

This(below) gives view of separating the functions to 2 ropes for more of a cleaner ratcheting/less herky jerky system once orchestrated:

(note sling lower on tree where might have tried pulling thru pulley first?/for same task)

Rigid levers can only capitalize on sine(forces across column), and greatest when at sine1/cos0 perpendicular force across device on minimal axis leaving maximum axis as cross axis availing to most leverage against (so can invoke length multiplier).

vs.

column use along maximum axis cos1 only availing minimal axis to side forces/if any.*

True column w/o side force carries CoG same at 10' as 20' or 40'(no length multiplier on even rigid cos axis)

>>to cross force tho that gives leverage of tiltability vs stability of base width so martial arts fighter squats lower and wider(like pyramid) to stabilize against cross axis hit best type model.

Taking massive low weight off tree raises CoG w/o widening base by contrast; and is probably loose on it's pulls of weight distribution where was more tightly stabilized before (in)human treatments.. Am trying to show this as all the same, that we individually already know, at least pieces to, and how they come together to same picture have always known..for can be a lot of forehead slapping w/telltale palm print left as things start clicking, but of c(o)urse it is only logical that....geeeeez..

.

Ropes are allowed to also swap velocity for power inline(!) capitalizing on cosine, but yes in segmented lengths/additive, multiplier comes in still only on cross axis in swig*, or stacking/daisy chaining or here even more conservation of force by insetting/compound pivots(?) to within system.

sine leverage across column includes length, not cosine force aligned to column/no distance consideration; extra length is just more reach for forces.

.

It all is conservation of forces, no free rides; must work with what is there from input force volume (power x distance).

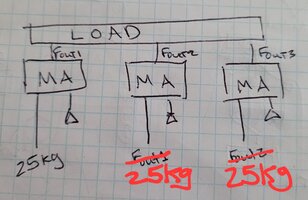

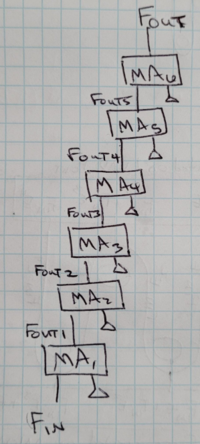

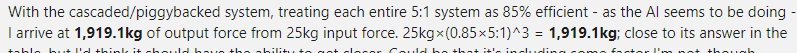

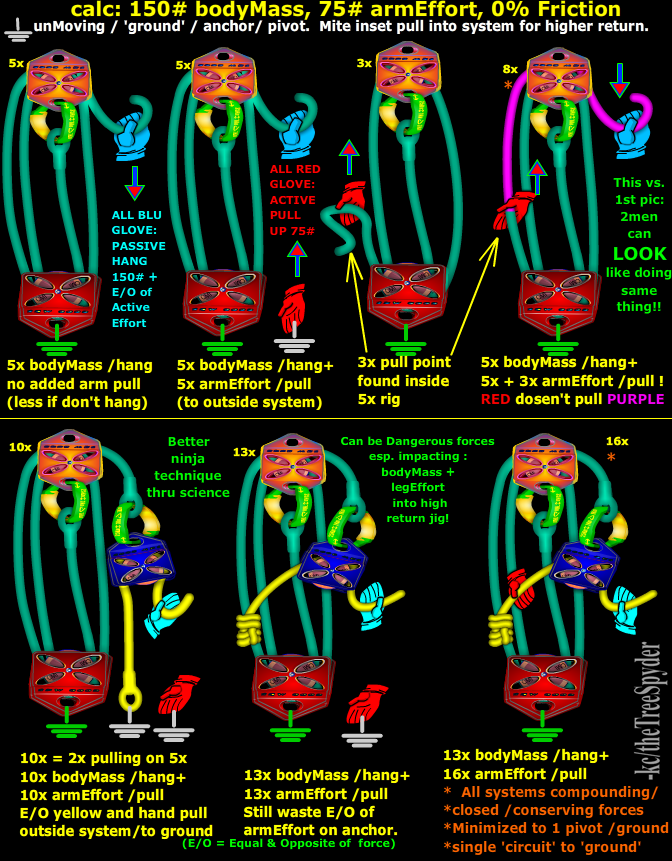

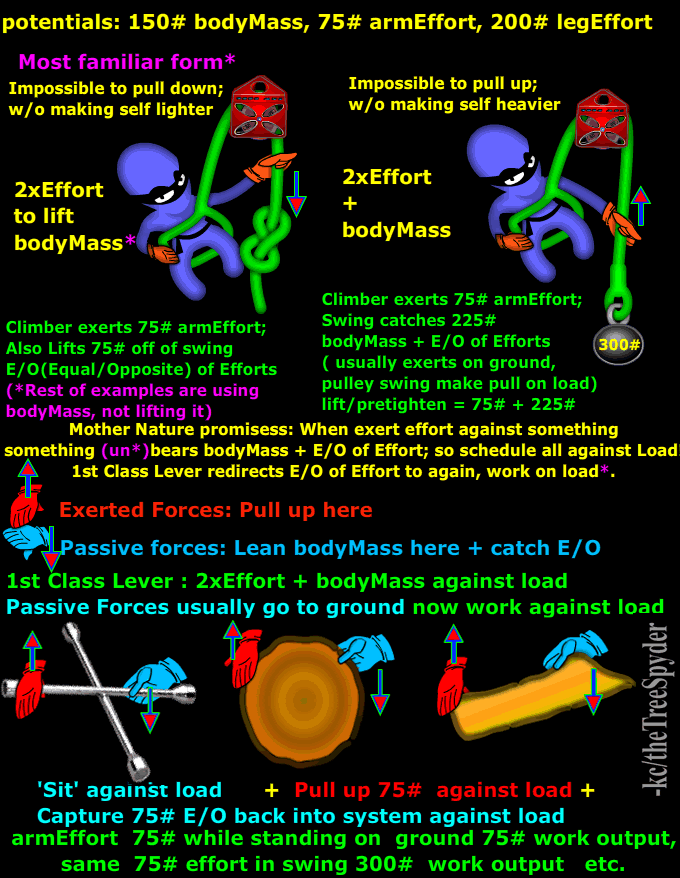

Insetting to me taps into also using the promised, but seemingly elusive E&O force also(other half of yin/yang too as magician's other sneaky hand), that is usually unwatched so as to be 'discarded'/dead-ended to anchor outside the system as a pivot machine as like see-saw. Compounding this into the system as a secondary input, rather than 'throw away' is model. Also gives 2 components: effort(and it's E&O) as 1 and then bodyweight. System only needs 1 external machine pivot/'ground'.

.

In normal pulls exert effort to the limit of bodyweight;(unless pull on anchor for more, insetting puts that pull inside system too!!)

i always and all ways now play the chess game where i can to exert effort + it's E&O thru system on either side of pivot (E&O directions captured) then add bodyweight (instead of it being a limit of input alone). Then, work leg force in as effort when can, and can impact with weight and sometimes effort too, in tandem, or as bump to move and chaser, or either effort or bodyweight input holds system at bay while the other input type impacts.

This stuff is a game changer, and if can grasp it, rest from before is cake and rules even more so pervasively confirmed. Even if don't get, is probably right direction to try to reach to..

.

Rigid cross axis vs. Flexible inline leverage classes in systems as same in many ways can see many parts of one thru the other if already familiar or just confirm; kinda it's own parity check as trying to model.

DIRECTION of force is a very much overlooked important item.

a class1 lever is the ONLY one that reverses Direction, classes 2&3 preserve direction as swap velocity (mph) for power(force) just like 10speed or transmission, can have high speed or granny hill climb from Zer0, not both. Thus all leverage exchange systems can be used also as like transmissions to negotiate speed if that is focus(use in reverse to gain power by swapping input/output). From an input force volume conservation in same amount of time at one end of lever (input or output) can have more distance covered(mph) vs. compressed to less distance of more force(slower mph). Dilute force to more distance or compress distance to more power, no free ride, in fact always some co$t of inefficiency/friction (or Kennedy bullet would still be flying theory).

Several decades of extreme focus into this fascinating chase.

*

EXCEPTION: rope/flexibles class do NOT resist on the cross axis like rigids, so no distance multiplier

>>work instead by undermining the cosine trying to work, to then reveal sine to exploit, but no distance multiplier on cross axis input when go this route of tapping available forces.

>>there is still a non linear(not as additive power progression as pulley route noted) progression change for cos/sine change scale, but only for short range.