Hey guys this is my first post. I hope it's in the correct place! If not mods please move it.

My son and I have watched rec tree climbing for a while. After pricing all the gear it made us back off.

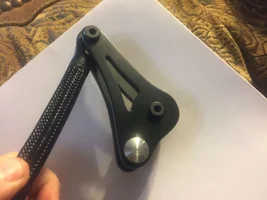

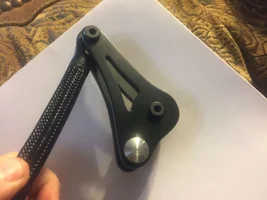

Well I own a machine shop and started seeing hardware. One that caught our attention was the rope wrench. Well I did my research and machined out one for myself.

I also machined and fabricated my own tending pulley and tether.

The tether is 12" split tail version.

The problem I'm having is the wrench isn't taking the weight off of the hitch enough to descend. It just locks and we have to unweight the hitch to disengage it. Wven still we can't get a decent from the hitch.

I've tried more loops less loops and a couple style hitches. Most I've watched used the VT so that's what we've attempted to correct or perfect.

One other thing is that the hitch seems to reach close to the wrench pulley when engaged. It doesn't appear that the wrench is cranking down enough under weight.

For the hitch I'm using a GM 21" eye to eye 8mm on a 11mm static line.

I'm gonna load a few more pictures tell me what y'all think.

My son and I have watched rec tree climbing for a while. After pricing all the gear it made us back off.

Well I own a machine shop and started seeing hardware. One that caught our attention was the rope wrench. Well I did my research and machined out one for myself.

I also machined and fabricated my own tending pulley and tether.

The tether is 12" split tail version.

The problem I'm having is the wrench isn't taking the weight off of the hitch enough to descend. It just locks and we have to unweight the hitch to disengage it. Wven still we can't get a decent from the hitch.

I've tried more loops less loops and a couple style hitches. Most I've watched used the VT so that's what we've attempted to correct or perfect.

One other thing is that the hitch seems to reach close to the wrench pulley when engaged. It doesn't appear that the wrench is cranking down enough under weight.

For the hitch I'm using a GM 21" eye to eye 8mm on a 11mm static line.

I'm gonna load a few more pictures tell me what y'all think.