ATH

Been here much more than a while

- Location

- Findlay, Ohio

94" DBH Hackberry has been dropping some limbs. I deadwooded the tree in 2018. There are a few dead branches now, but its lost some live branches. Took out a privacy fence (owners aren't too exited about that). If it goes, it will take out 3 phase power & a bunch of communication wires, probably a detached garage or three, parked cars, and maybe reach some apartments with enough force to cause some damage.

I was asked to provide an assessment/make recommendations. @macrocarpa and I discussed a little. Thought I'd post here too to get some more input. I have some thoughts, but will hold those for a day or two just to see what we get here based on pictures.

At some point this was 2 trunks that grew into one - probably never truly grafted. A codominate leader from one of the trunks broke out leaving a split between the two trunks. That's what brought up the immediate concern.

Whole tree:

Split from south side:

Break out from the north side:

Whole tree (most of it, anyhow) from the north:

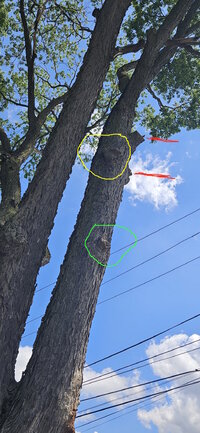

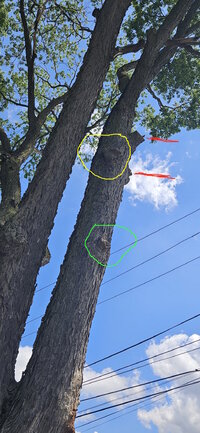

This is looking from the NW - west-most limb. Honey bees in yellow circled area. Visible hollow circled green. Relatively new stubs from cuts where there is no visible cavity (very near bee hole) with red lines pointing to them:

From the east - that break out also happened since 2018.

Back to the south side...when I tap with a mallet, it sounds - well, like a drum between the white lines:

I didn't have the resistograph with me today. Honestly, not sure how helpful that will be. Not even sure sonic tomography would be great here since it is 2 separate trunks. I'm sure it would show separation there, so I'm not sure it could give a good pic of what's really going on in this beast.

I was asked to provide an assessment/make recommendations. @macrocarpa and I discussed a little. Thought I'd post here too to get some more input. I have some thoughts, but will hold those for a day or two just to see what we get here based on pictures.

At some point this was 2 trunks that grew into one - probably never truly grafted. A codominate leader from one of the trunks broke out leaving a split between the two trunks. That's what brought up the immediate concern.

Whole tree:

Split from south side:

Break out from the north side:

Whole tree (most of it, anyhow) from the north:

This is looking from the NW - west-most limb. Honey bees in yellow circled area. Visible hollow circled green. Relatively new stubs from cuts where there is no visible cavity (very near bee hole) with red lines pointing to them:

From the east - that break out also happened since 2018.

Back to the south side...when I tap with a mallet, it sounds - well, like a drum between the white lines:

I didn't have the resistograph with me today. Honestly, not sure how helpful that will be. Not even sure sonic tomography would be great here since it is 2 separate trunks. I'm sure it would show separation there, so I'm not sure it could give a good pic of what's really going on in this beast.