- Location

- Washington

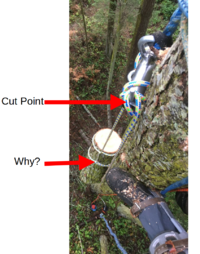

Hi all, I'm new here, but have been gleaning knowledge from the forum for awhile. I just finished this miniature version of a RC-type porty (I know the welds aren't pretty, but I have confidence in them). I have seen many home made devices on the internet, but not of this style and small size. I made it with 1 1/2" steel pipe, so it is 1.9" diameter, the same as the buckingham small porty. 1/2" seems to run well on it.

I have some questions after making this thing. I have not used a port a wrap before, but have plenty of experience with lines on bollards and capstans.

What opinions do you have about suitable cylinder diameters for different sizes of rigging lines?

Is a longer than absolutely necessary cylinder a benefit?

I have never seen or heard of a portawrap breaking. Does this ever happen?

Thanks!

I have some questions after making this thing. I have not used a port a wrap before, but have plenty of experience with lines on bollards and capstans.

What opinions do you have about suitable cylinder diameters for different sizes of rigging lines?

Is a longer than absolutely necessary cylinder a benefit?

I have never seen or heard of a portawrap breaking. Does this ever happen?

Thanks!