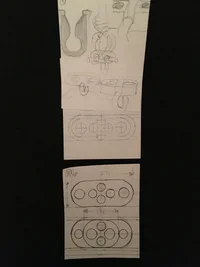

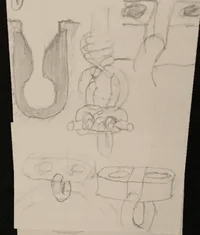

The following is greatly inspired by the most excellent idea of the dogbone from the Hitch Hiker. Just put the friction hitch legs through the holes and tie stoppers.

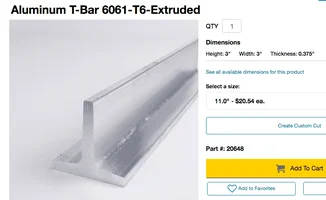

After a few more complicated designs, this was the simplest, and seems the best for this type of design. With the small plate, hitch cords don’t need eyes or have to be a set length to function on certain hitches. The VT, and other hitches will be improve by being able to adjust the leg length. This would also make for cheaper hitch cords for those that buy eyed cords now. This is the first design I was able to make with what I had on hand. There will be a couple others when I get some more aluminum chunks. Here are a couple other ways to use.

After a few more complicated designs, this was the simplest, and seems the best for this type of design. With the small plate, hitch cords don’t need eyes or have to be a set length to function on certain hitches. The VT, and other hitches will be improve by being able to adjust the leg length. This would also make for cheaper hitch cords for those that buy eyed cords now. This is the first design I was able to make with what I had on hand. There will be a couple others when I get some more aluminum chunks. Here are a couple other ways to use.