The creamy yellow cord is Sterling’s 6.8mm RIT 900, a single braid that flattens to be more like webbing. I’ve used locked brummels before, but the Kevlar-like, Twaron has a dubious past when used as a hitch cord. Adding a 3mm dyneema core turns it into the cover instead, still works very good, and about double the thickness of most covers. The black one is a Hollowblock2 with a core.

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Show off them splices

- Thread starter Jman

- Start date

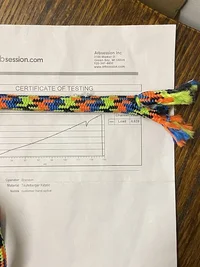

Finally sent the improved version in for testing and got better results with burying the cover, just a loss of 11% of the break strength, and still low profile.While trying to figure out how a Lankhorst A3 splice is done, the splicing is all done in the eye, I came up with another way to make eyes in the twisted parallel cored ropes. Xstatic’s break strength is 7192 lbs, the left one broke at 6031, and the other, which had a foot and a half feet piece of 3mm Amsteel in the eye, at 6621.

View attachment 94922

After sending the two never nude naked eye spliced examples in to be tested, I thought of another method to give a better looking end result, might be a little stronger also.

View attachment 94923

Also trying different methods to get more flexible double eye friction hitch cords.

RyanCafferky

Been here a while

- Location

- Hood River, Oregon

Recently I have been resplicing my employees climbing lines. Did one yesterday that was so dirty that I had to wash it first. It was so filthy I couldn’t get the core out. Being a contract climber my gear lasted forever. I would throw out ropes based on age rather than because it was worn out. Having employees is a whole different ball game.

Attachments

Naturarbo

Participating member

- Location

- South Portugal

Pulling my hat to you @BrockyFinally sent the improved version in for testing and got better results with burying the cover, just a loss of 11% of the break strength, and still low profile.

Also trying different methods to get more flexible double eye friction hitch cords.

View attachment 98958

Very nice, if you would be in Europe, I would be buying just to feedback...I have done a few hitch and never was 100% happy.

I picked it up right away, an early masterpiece using UltraTech and Samson’s instructions on the left.

The black one’s twisted core strands were removed and and a small dyneema braided one put in. I figure out which size, when doubled in diameter, will slide into the cover, with little alteration of its diameter. In between the two splices, Tuck-Buries, some of the twisted strands are buried to match the double diameter, or slightly smaller.

The purple one started out the same, but the splice buries are both reduced by half, and overlap the whole length between the eyes.

The black one’s twisted core strands were removed and and a small dyneema braided one put in. I figure out which size, when doubled in diameter, will slide into the cover, with little alteration of its diameter. In between the two splices, Tuck-Buries, some of the twisted strands are buried to match the double diameter, or slightly smaller.

The purple one started out the same, but the splice buries are both reduced by half, and overlap the whole length between the eyes.

ghostice

Been here a while

Has anyone got any tips for splicing Scion 11.5 mm? I did a Class 1 splice in it this week and had a bear of a time wrestling with the core which seemed to unravel if I looked at it sideways.

When I extract cores on double braid splice I always tape it before fully extracting. Leave about 1" inside the cover then tape the core where it exits. Pull out the remaining core and tape the end.Has anyone got any tips for splicing Scion 11.5 mm? I did a Class 1 splice in it this week and had a bear of a time wrestling with the core which seemed to unravel if I looked at it sideways.

ghostice

Been here a while

If I understand, It wasn't end management but more when I was trying to push a fid thru to get the cover into the core - never had a splice where the core went so "all over the place" every time I touched it. Wondered if it could be static or something. In a single malt induced haze (what - again . . . ??) wondered if some hair spray would'a helped? Or wetting it? Kidding but this one was odd. Just thought I'd ask. Thanks for your response - never thought about taping the whole shebang. Cheers.

Addenda: OTOH - wonder if anyone has ever tried "Wet Splicing" - i.e. splicing a soaked rope?

Addenda: OTOH - wonder if anyone has ever tried "Wet Splicing" - i.e. splicing a soaked rope?

I use scion for one of my lanyards and also as my chainsaw lanyard so I've spliced it multiple times. I always wait until after I pull the core back into the cover to insert the cover into core. Never had a problem with the core wanting to unravel doing it that way since it's held in place at both endsIf I understand, It wasn't end management but more when I was trying to push a fid thru to get the cover into the core - never had a splice where the core went so "all over the place" every time I touched it. Wondered if it could be static or something. In a single malt induced haze (what - again . . . ??) wondered if some hair spray would'a helped? Or wetting it? Kidding but this one was odd. Just thought I'd ask. Thanks for your response - never thought about taping the whole shebang. Cheers.

Addenda: OTOH - wonder if anyone has ever tried "Wet Splicing" - i.e. splicing a soaked rope?

ghostice

Been here a while

I found this video where Eric Foresman splices Sterling Tendril - he buries the core first. Thanks

New threads New posts

-

test

-

-

-

-

Light 14 or 16" narrow kerf bar for 200t or 201t

- Started by southsoundtree

- Replies: 9

-

-