RyTheTreeGuy

Branched out member

- Location

- Canada

Point taken! But will it pass through a Zigzag? That would be cool.

It is very cool...

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

Point taken! But will it pass through a Zigzag? That would be cool.

Hahahaha... Yes! Yes! my friend!!!Point taken! But will it pass through a Zigzag? That would be cool.

OK, now I gotta learn it.Hahahaha... Yes! Yes! my friend!!!

That is the whole point of the splice!! The Zig-Zag, Zillon, SpiderJack, Art positioner, smaller thimbles & rings regular DB splices have trouble threading from the ground level, etc, etc, etc..

It's not just this Cousin brand either, is FTC & Courant as well. Only ones who haven't come on board are stateside manufacturers which confuses the hell out of me & to be honest makes me think these companies need to take a look at their approach as to what they consider user friendly or cutting edge. Maybe there's a reason they not making stuff like this.. who knows.. i just think it has to do with a companies ability to innovate & look past traditional methods.

Does that turn your grumpy pants into happy pants?

Hahaha... When you got it figured out & somewhat documented please fill us in!!OK, now I gotta learn it.

Redbull?

Like Redbull gives you wings, Redbull? They have the deets on this splice??

If you end up disecting your splice make sure to take some pics!

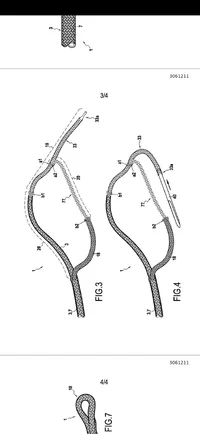

That almost seems like cheating.Found the patent.

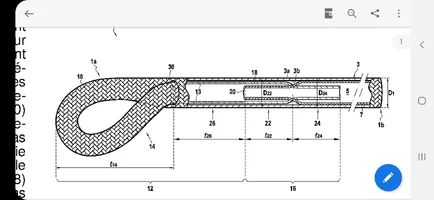

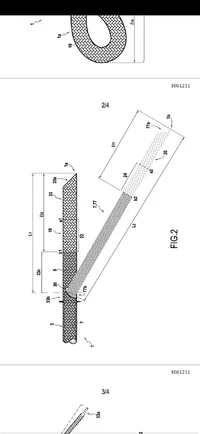

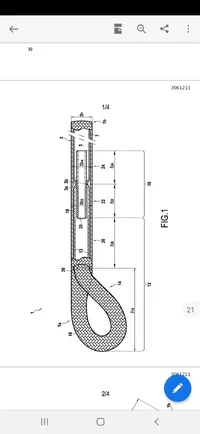

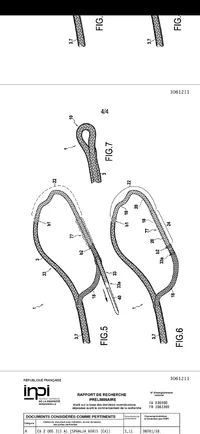

FR3061211A1 - ROPE AND METHOD FOR MANUFACTURING SAID ROPE - Google Patents

The present invention relates to a rope (1) comprising a braided tubular main sheath (3), comprising at least n plaited wicks, and having an inner volume (5), and a braided tubular main core (7), comprising at least p wicks braided, housed in said inner volume (5) of the main sheath (3), n and p...patents.google.com

View attachment 63027View attachment 63028View attachment 63029View attachment 63030View attachment 63031

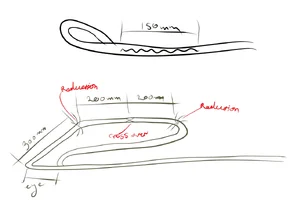

It's definitely just double braid.So this rope has a braided core, from the FTC video I thought it had twisted parallel strands. Maybe there is a skinny splice for that type of rope also.

Pretty much on point. I converted to inches to do my splice and those measurements are what i gotThis is the splice with the cover opened.

View attachment 63067

View attachment 63068

View attachment 63069

View attachment 63070

I think there is a mistake in your instructions for where the core exits. It should be at the first mark below the eye, where the cover reduction starts.

The patent helped a lot with knowing what I was looking at while slitting the cover. I posted earlier that I thought the bury went for eight feet, come to find out it was an imbalance of the core and cover after the splicing. The diameter changed disappeared after opening up the cover.

Brock.. u ever think about doing a YouTube channel with your experiments? I mean, you put a lot of effort into this stuff & actually follow through with testing afterwards so you know what works & what doesn't... If you played your cards right, you could probably make some paper with advertisers to offset your "heathy" addiction...lol..This is a nice and easy splice once it’s sorted out. My reducing of the cover and core were sloppy, but this half inch Stable Braid still turned out.

View attachment 63175