dspacio

Branched out member

- Location

- Narragansett Bay

returned to a Silver Maple, which had one stem fall in a spring storm, to bring down the rest.

three main stems, all leaning away from the yard, over a fresh new fence.

not huge (13-22dbh), each progressively smaller, and with more lean.

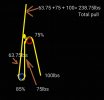

Centers of Gravity lean away about 2 ft, 5 ft, and 8 ft, respectively.

Set up a great pull system to a maple and clothesline post way across the yard.

with this I could tension with a 2:1, 6:1, followed by more with a 10:1.

25% face cuts. backcut a bit and tension. tree went down revealing rotten middle.

first went well (could have been felled with just wedges, served as test tree)

the second was the highest risk, big section, CoG needs to move maybe 6 feet. I had a decent high crotch to handle the tension. made my final reality check after getting it all set. crucial to the plan was not running out of rope between the blocks.

to break this down: pull line from tree ends in a pinto pulley, through which one end of nystron rope runs to a block on tree, back to another pinto prussiked on that leg; other end meets a 5:1 fiddleblock anchored to clothesline post.

It's the first time I used M.A. multiplier, by pulling a 2:1 system with more advantage. As I understand, the force multiples (2:1 x 3:1 = 6:1 )

Generally I have seen pulls like this done with winches, trucks, machines; never with rope and man alone, so I was in an uncharted water feel. It was not a play scenario, I had a spotless fence under a hard leaning tree (20 and 40 degrees off vertical?).

I trusted to principle, my assessment of tree weight and whether I was balancing the force I would need with the amount of reach I needed to move the tree that far.

I was able to start hauling stem 2 for real while still having about 30% hingewood (with a bit of core nipped out). I truly did run out of rope on the extra MA setups, right about the time the tree was nearing a point of balance, and I could haul right on the 2:1 directly and bring it on home.

The 3rd stem went about the same, though I needed to haul it way further, it was about half the weight and went without a hitch.

Reason I am sharing. Some night I remember reading about force multiplier in MA systems, no idea why, it just came up and I logged it as a cool tidbit. I showed up yesterday prepared to climb this thing and piece it out, maybe fall it. Then I saw the new fence, meaning it was more rigging. It was with a few doubts I considered hauling these things over. Ultimately this trust in known methods, just in a new combination, let me fall these safely and in half the time climbing could have.

So the half hour of reading about M.A. multiplier saved me half a day of work. Sometimes I study after seeing the challenge, but this time a whole bunch of things came together (including face cut and backcut principles, using hinge, the experience to expect rotten core) so I could bring these down in a good controlled way.

I also was super jazzed about the variability this pull system gave me. I recently set up that dedicated 5:1 with some of that maple leaf double braid, super handy to have as an easy addition.

no winch required. any advantage can be had, just avoid making and fighting friction.

Anyway, enough writing.

three main stems, all leaning away from the yard, over a fresh new fence.

not huge (13-22dbh), each progressively smaller, and with more lean.

Centers of Gravity lean away about 2 ft, 5 ft, and 8 ft, respectively.

Set up a great pull system to a maple and clothesline post way across the yard.

with this I could tension with a 2:1, 6:1, followed by more with a 10:1.

25% face cuts. backcut a bit and tension. tree went down revealing rotten middle.

first went well (could have been felled with just wedges, served as test tree)

the second was the highest risk, big section, CoG needs to move maybe 6 feet. I had a decent high crotch to handle the tension. made my final reality check after getting it all set. crucial to the plan was not running out of rope between the blocks.

to break this down: pull line from tree ends in a pinto pulley, through which one end of nystron rope runs to a block on tree, back to another pinto prussiked on that leg; other end meets a 5:1 fiddleblock anchored to clothesline post.

It's the first time I used M.A. multiplier, by pulling a 2:1 system with more advantage. As I understand, the force multiples (2:1 x 3:1 = 6:1 )

Generally I have seen pulls like this done with winches, trucks, machines; never with rope and man alone, so I was in an uncharted water feel. It was not a play scenario, I had a spotless fence under a hard leaning tree (20 and 40 degrees off vertical?).

I trusted to principle, my assessment of tree weight and whether I was balancing the force I would need with the amount of reach I needed to move the tree that far.

I was able to start hauling stem 2 for real while still having about 30% hingewood (with a bit of core nipped out). I truly did run out of rope on the extra MA setups, right about the time the tree was nearing a point of balance, and I could haul right on the 2:1 directly and bring it on home.

The 3rd stem went about the same, though I needed to haul it way further, it was about half the weight and went without a hitch.

Reason I am sharing. Some night I remember reading about force multiplier in MA systems, no idea why, it just came up and I logged it as a cool tidbit. I showed up yesterday prepared to climb this thing and piece it out, maybe fall it. Then I saw the new fence, meaning it was more rigging. It was with a few doubts I considered hauling these things over. Ultimately this trust in known methods, just in a new combination, let me fall these safely and in half the time climbing could have.

So the half hour of reading about M.A. multiplier saved me half a day of work. Sometimes I study after seeing the challenge, but this time a whole bunch of things came together (including face cut and backcut principles, using hinge, the experience to expect rotten core) so I could bring these down in a good controlled way.

I also was super jazzed about the variability this pull system gave me. I recently set up that dedicated 5:1 with some of that maple leaf double braid, super handy to have as an easy addition.

no winch required. any advantage can be had, just avoid making and fighting friction.

Anyway, enough writing.