SoftBankHawks

Branched out member

- Location

- Japan

Does any one do it?

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

I'd guess that it is measurable to around 10-15%. Just as any other method, knotting/splicing/stitching is repeatable and measurable to certain parameters. Once the outer strands have been cut they and the rope are much more susceptible to further damage. End to end splices don't work in my mind cause of the amount of slack moving around, they can pop out way to easily. This may be a method for ropes other than db, if a method at all !I have a 24 strand double braid that has four picked strands. The inside core is still not visible and is unaffected. Assuming a 50/50 distribution of load, doing the math I still have 90% strength in this rope. Just for fun let's say I tie an Alpine butterfly over that defect to isolate it. Now my rope is down to about 65%. How much sense would that make?

I don't think you can consider the strength even if you could find a way to stitch those strands together because it's really not measurable.

No, not that at all.I'll guess that he is trying to join the ends of two ropes together without increasing the outside diameter.

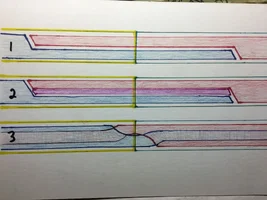

View attachment 42035

On number one, the covers are slid back and the cores are each reduced by half, than laid on top of each other and the covers milked back together.

On number two, reduce the cores more than half and insert a piece of dyneema webbing for added strength.

On number three the cores are reduced by half and buried into each other, after being rebraided.

All three would need some kind of stitching to keep them together under low load. Testing would determine how long the buries would have to be.

Ok my second guess is......I don't have one. I thought it was TRT related and you needed a continuous loop. Oh well,I enjoyed working on that problem even though wrong.(Guess I don't win the prize either!)

Have you seen Splicing Kernmantle Rope by DW Tomer in Nylon Highway #12?

IIRC, there's at least one other method they've published for kernmantle rope (as part of another treadmill build), but I can't seem to find it.

That's coool. I've been doing some reading up on caving these days, managed to find 'Prusiking' by Robert Thrum too, awesome stuff and it all helps to understand why we got to where we are now. Manufacturers and Industry guidelines aside there is an awesomly huge world for us riggers to explore, as individuals. Love it !Ahhh - found it!

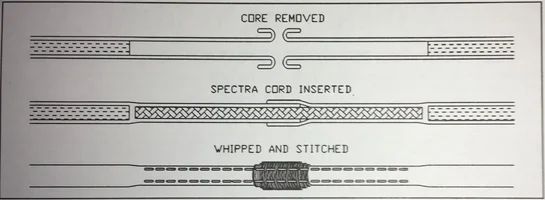

From Climbing Treadmill by Pete Sauvigne, Nylon Highway #35:

Making the splice is critical to the success of this system. A kernmantle rope is required, I use standard PMI. On each end of the loop piece: Pull out the core about 10 inches by aggressively sliding the sheath along the core. Cut off this piece of core, and slide the sheath back to its original position leaving a rope with hollow ends. It is helpful to fold back about 1 inch of the sheath and tape the end to keep it from fraying. Then insert a 12" piece of 5.5mm Spectra cord into the holes. The Spectra cord should bottom out against the original core. When it does, tack it down with a sewing awl to keep it in place. Take one end of the sheath, remove any tape and tie it to the Spectra cord with heavy awl thread about 1 inch past the center of the splice. Smooth out this side of the sheath and cut off any excess. Now overlap the other end of the sheath and tie it down with about 1 inch overlap. Again cut off any excess. Now whip the splice for about 1 1/2 inches over the sheath lap. Stitch through the sheath and the Spectra cord over the entire 12 inch length, including through the whipping. Make two stitching passes, 90 degrees apart. The splice will require periodic inspection and re-whipping every 200 revolutions or so. DO NOT USE 6mm nylon in place of the Spectra cord. Such splices break at about 30 revolutions, while my Spectra cord splice still holds after about 400. A rack will work for the rappel device, but it will tend to wear the splice more quickly.View attachment 42321