Thanks for the comments, guys, here and on YouTube.

I think the issue of bend radius is real and I’m pushing it. But perhaps not as much as you might think…

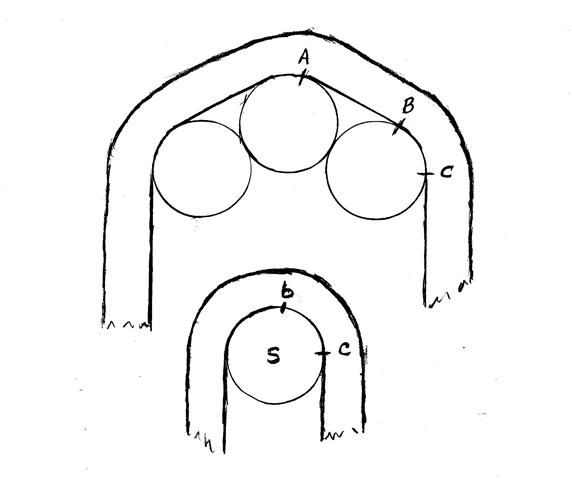

The WM rings have a section diameter of 11.7mm. That’s considerably fatter than a normal steel arborist rigging ring. So in the hanging, 3-ring configuration the rope sees a 1.4” effective pulley diameter (2x11.7 + 1x12.0). I’m good with that.

In the 2-ring choking configuration, the effective diameter drops to 0.92”. That’s looking small, to be sure. But a good bend radius is a function of the rope being used. I chose the small arborist ring to specifically prevent loading the whoopie with a big rigging line. There’s no room for more than a 9/16" line. It’s like a micropulley stops you from threading up a big line, even if you don’t intend to load it heavily. The small ring is there to protect for bend radius.

I’ve tried the whoopie on three rigging lines:

1/2” Stable Braid

9/16” Stable Braid

1/2” Treemaster (a tri-line)

The Stable Braids both look perfectly happy. Very nice flexibility. The Treemaster, not so much. It doesn’t look completely pissed but it definitely looks annoyed.

I really don’t know what the long-term durability will be for a small bull line. Of course, two rings is perfectly fine for a climbing line, but we’re not hitting it with repeated impact loads.

I really would like some feedback on this.

If this is a major issue for you, there are two additional things you could think about:

1) If you need the choking, round turn the adjustable eye and use three rings.

2) If you’re a traditionalist, you could be saying “If I want a light alternative to my big block, I’ll get the little CMI or something for a hundred bucks.” Fine, but you’ll need a sling for it. Hmmm …you could pull the adjustable eye through the big rings and hang the CMI on a Rigging Whoopie. Now the Whoopie can earn it’s keep with a few extra tricks other than just holding the block.

OF