Shadowscape

Been here a while

- Location

- far north

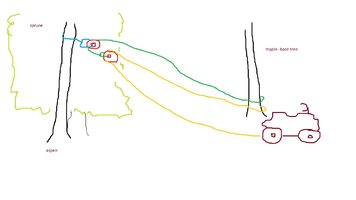

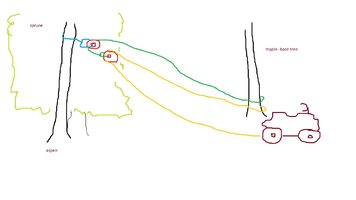

I have worked solo for the last 15 years, so I'm not really up on what others are doing these days except for what little I have caught on the internet from time to time. I have not seen anyone using large rigging rings as snatch blocks. I find myself using them more for that than as lowering rings. As a matter of fact I have more of them spliced onto dead eye slings and what seems to be a reinvention of a once highly used sling you now call ultra slings (We just made them with knots) through the holes rather than around the outside. At any rate, is there anyone besides me out there using the rings as snatch blocks? Or am I a weird duck? About a month ago I pulled a large Aspen blowdown out of a standing Spruce with three of these and a small 4 wheeler. Oh, and about 300 feet of 5/8 rope. But it was easy and much safer than trying to cut it out of there.

Not good at drawing. Sorry. One more set in there I forgot to draw.

Not good at drawing. Sorry. One more set in there I forgot to draw.

Last edited: