beastmaster

New member

- Location

- Calavaras co.

I have a couple questions I hope someone can help me with. If I set up a single rope through a pulley on a tree opposite the one I'm rigging. Run it to the tree being rigged and secured with a bowline under my face cut. Tieing a short line to the piece im dropping and clipping it to the rope so when it falls it'll be supported by both trees. Each tree taking half the force, compared to negitive rigging from a single spare.

Am I correct in that assumption?

Now what if I uses two ropes, the one from the opposite tree attracted to the piece above the cut, closer to the top, then a pulley set up for negative rigging from the tree being. When the piece fell it would also be supported by both tree.

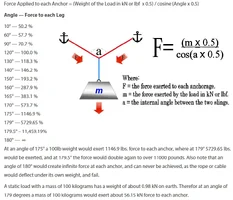

I have some really dead tops I have to rig out. I don't feel safe negative rigging them. Wires and obstacles under them so I can't let them run much. I can zip line out 8 ft pieces after the tops are out. Zip lining out the tops would side load em to much. Can someone give me a physics lesson.

Am I correct in that assumption?

Now what if I uses two ropes, the one from the opposite tree attracted to the piece above the cut, closer to the top, then a pulley set up for negative rigging from the tree being. When the piece fell it would also be supported by both tree.

I have some really dead tops I have to rig out. I don't feel safe negative rigging them. Wires and obstacles under them so I can't let them run much. I can zip line out 8 ft pieces after the tops are out. Zip lining out the tops would side load em to much. Can someone give me a physics lesson.