I just got the last one. Thanks for the tip!Hi Burrapeg, I just purchased a Rollgliss R500 on ebay: https://www.ebay.com/itm/143177649662

Question for you: how did you get the manual handle off and replace it with a drill?

Navigation

Install the app

How to install the app on iOS

Follow along with the video below to see how to install our site as a web app on your home screen.

Note: This feature may not be available in some browsers.

More options

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Reliable DIY power ascender

- Thread starter Burrapeg

- Start date

Burrapeg

Been here a while

- Location

- Puget Sound

Yeah, a cross pin holds the original handle. I had to turn my shaft down a bit in the lathe to fit my DeWalt drill but some larger drills may be able to handle the 5/8 shaft.

I hope your Milwaukee works for you. I had one and it would ascend pretty good but the clutch in the drill would not stay engaged and would allow you to slip back down. I am a bigger climber so YMMV. I ended up getting the dewalt that @Burrapeg recommended. Try it out low and slow as with anything else.I'm going to guess my Milwaukee 18V Fuel will work, it sure can drive ice auger.

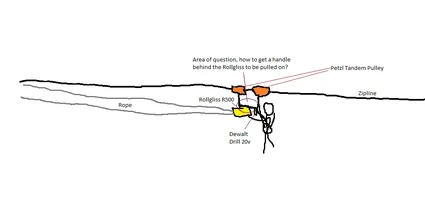

I'm planning to use my Rollgliss R500 to get myself and others back up a 200' backyard zipline. Currently someone has to be pulled all the way back to the top (in a tree), I'm hoping this will let people get themselves back up to the start so they can just release and zip line over and over. See attached image. The thing I'm wondering is if a 90 degree arm connecting the drive shaft to the drill would position the drill handle more ergonomically in the vertical direction for the user on the zip line? I've been considering getting something like a power drill right angle extension, https://www.amazon.com/s?k=power+right+angle+drill+extension

Any other ideas how to build a zip line retriever? thanks

Any other ideas how to build a zip line retriever? thanks

Attachments

climbstihl

Branched out member

- Location

- Germany

The easiest thing to do would probably be to just anchor the rollgliss and set up a continuous loop, and the people just hang onto the rope or use an ascender to hold them, then release at the top. That would eliminate doing it on your own though. The problem when doing it by yourself is how do you get it back? Do you take the rillgliss off and take it with you when you ride the zipline?

climbstihl

Branched out member

- Location

- Germany

Keep in mind you won't have a termination that can pass through the rollgliss (unless splices fit through??), so you will need to either reverse it, or stop it sometimes and pass the knot. You should be able to just keep reversing every cycle to keep it working.The idea of a continuous loop is a good one, then users could just hold on to the rope until they get to the position they want and let go. For single users I'd need to figure out how to wire up a remote control for the power drill.

So the first time you ride you hold onto the first side, you slide down, reverse the direction of the drill, hang onto the otherside.

I'm not sure that I would want to trust my safety to a remote or another person at ground level. You would be relying on them or the remote to stop it if you got in trouble. I understand you are taking the same risk when doing crane work, but I would trust a trained crane operator a lot farther than a bunch of cats B's,ng around the base of the tree. Justy thoughts and I may be nuts?

climbstihl

Branched out member

- Location

- Germany

What we're talking about right now is just holding on to a moving rope to tow you up the zipline, you are only connected to the zipline and if you let go, you go back down. I would view that reasonably safe, there is no big risk of getting tangled or something in the moving rope.

climbstihl

Branched out member

- Location

- Germany

@paul_pdx On the topic of the 90° connector, that should work, it's even used in a commercial version, as can be seen here at 0:49.

It is indeed compact. I picked one up fairly cheaply off of ebay but in my haste didn't pay attention to the photos and unfortunately it didn't have the hand wheel and extended shaft! (brilliant I know) I have a friend that is a machinist and he claims he can make a new shaft to replace the shorty so all is not lost!!That looks interesting. Nice and compact.

samsquatch

Participating member

- Location

- SE MN

Ordered my R550 this week. We will see if I can make it work for production.

I hope to be using a Milwaukee 2803 drill (M18 Fuel) with the setup, and will report back here about clutch slippage. I have lots of M18 tools now, so really hoping use it - but if it slips I will find one that doesn't slip.. I hate DeFault, I'd probably try ManKita first!

Nice, the skylotec is compact. Appears the gear ratio is much lower than the Rollgliss, or at least the drill is in a lower RPM mode.

I hope to be using a Milwaukee 2803 drill (M18 Fuel) with the setup, and will report back here about clutch slippage. I have lots of M18 tools now, so really hoping use it - but if it slips I will find one that doesn't slip.. I hate DeFault, I'd probably try ManKita first!

And yet another device!

Nice, the skylotec is compact. Appears the gear ratio is much lower than the Rollgliss, or at least the drill is in a lower RPM mode.

I will be anxiously awaiting your results with the Milwaukee drill. I have to agree, i have never been a big fan of dewalt for real working environments.Ordered my R550 this week. We will see if I can make it work for production.

I hope to be using a Milwaukee 2803 drill (M18 Fuel) with the setup, and will report back here about clutch slippage. I have lots of M18 tools now, so really hoping use it - but if it slips I will find one that doesn't slip.. I hate DeFault, I'd probably try ManKita first!

Nice, the skylotec is compact. Appears the gear ratio is much lower than the Rollgliss, or at least the drill is in a lower RPM mode.

Burrapeg

Been here a while

- Location

- Puget Sound

Oh, these new 20v brushless DeWalts are great! Damn near bulletproof.I will be anxiously awaiting your results with the Milwaukee drill. I have to agree, i have never been a big fan of dewalt for real working environments.

I used to use the dewalt tools years ago and using them day in and day out for work didn't impress me much at all. I will say that the new model that you recommended to use with the rollgliss has and is working flawlessly! So I guess they have improved some over the years.Oh, these new 20v brushless DeWalts are great! Damn near bulletproof.