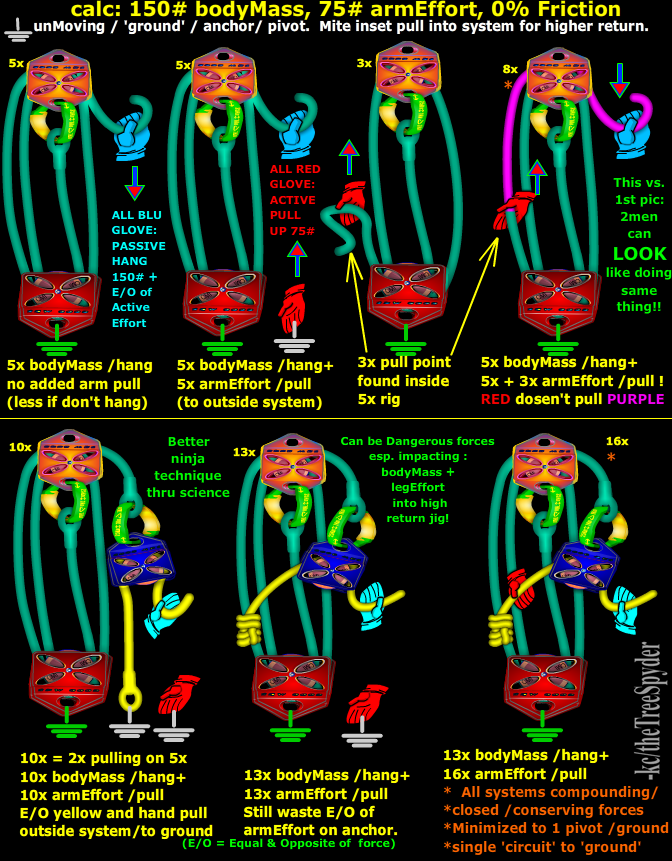

As the POTENTENTIAL for builds gradually in single increments, so then the inefficiency of the frictions

compound at a greater rate of building against(but from Zer0). Still the inverse of the potential is needed in distance, no break there. So if 5x potential actual yield is 2.9xEffort, it still cost$ 5xDistance for input. Rotational leverage builds in multipliers of length, linear leverage(pulleys) build more nominally in the amount of lengths used to the needed length type ratio(n) instead, much more incrementally, than a multiplier for rotational leverage, then so certainly much less than COMPOUNDING frictions around pulley as a low friction capstan arc. In the end, rotational or linear leverage just exchanges distance for power less inefficiency.

But have found other trick, sitting hours in DdRT, and the 2:1 over self, less friction magic,

.....by even more so conserving all forces spent to be against target even more. As see above, distilled that single principle out to carry with and play it against other challenges in then even rigid or round leveraging.

.

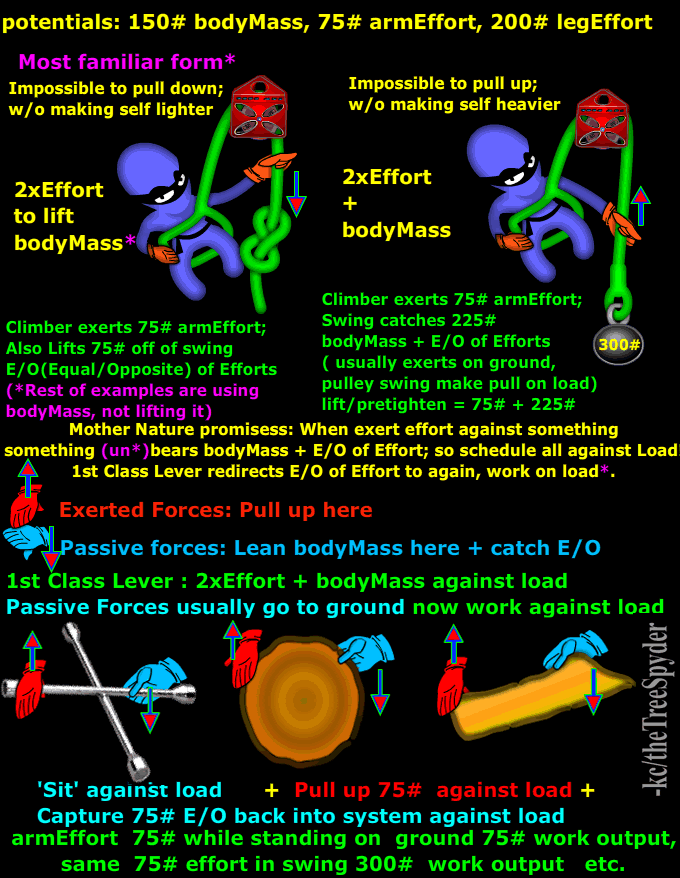

If take bodyweight out would only be left with Equal & Opposite against, so i try to do that, to dual opposing direction outputs, and add bodyweight back then against target, for more from same!

i imagine if standing on a scale, how to be as weightless as possible to the ground

(easiest for over head pull down), and then exert effort when that effort can't add nor subtract to/against bodyweight to ground(unless added handhold as shown above). All pulls directly against load(if any) are friction free then, or reduced per their position etc. As POTENTIAL increases, so does input distance, so may use normal 1 hand mode to chase out slack, then transmission switch to lower gear of more powerful 2 handing the system. i imagine some kind of go to lift legs up hard purposefully, sudden impact pulse to system, perhaps sliding wide for stability, maybe cheat to only 10-20# bodyweight on ground for stability like some kind of sudden, high impact, martial arts move, and then doing the equal/opposite opposings thru hands at same time, against 'opponent'/load.

GAME CHANGER: can be as 2nd man pulling at lesser point; within same system. As if standing at a lower leveraged input on lever to help against load fo' FREE!.

The idea extends then to not arm lift as input, but leg propulsion as input instead, to really get 'jump' on it. Still receive the equal/opposite of leg input at a hand position as secondary/lesser input position.

Even to 45 degree pull etc. try to invoke as much bodyweight as possible against target, plus pulls of opposing hands at leveraged distance apart. If pull with 1 hand, the equal and opposite added to or subtracted from is bodyweight.

These also give a more flexible usage of 2 part input system, one part can hold , the other impact, both impact or 1 impact and other keep motion going etc. A multi system to orchestrate, rather than mono.

Then for tiedowns, or tweak last lil'lift or perhaps a last input:

We have made the system iron bar tight as possible LINEARILY.

Next tighter is to then bend those iron bars shearing across at 90degrees, for the tighter they are, the more/less rubbery leveraged return from the purposeful bend of sweat/swig w/o the 'purchase' (olds-cool sailor speak)of line from the loaded bank to the unloaded bank of rope; thus removing rope from the loaded system to stretch rope and/or move target load..

Anchor 1 side of rope, over motor cycle handlebar and back down to a 5x1 can give POTENTIAL 10x if legs parallel, but also can sweat/swig some over handlebar, pinch to bar, hyper tighten more, then bend centers of over bar ropes towards each other some from their centers Then do other side, looking to compress shocks to either side/if any for softer ride. Such tie downs can bend some lighter metal parts/skins. Then secure rear of bike similarly with just 1 rope(2 in front on handlebar); a chess game with just a few pieces. Like gymnastics etc. something you study and then force thru your own body to proper positions to pull of the trick.

1 co$t to note is that in these 'closed' systems BOTH non input system points are equal.

Where a 5x compersssion jig down, has 5x POTENTIAL against load, but only 4x against machine pivot postion.

Witht he tweak they are equal 8xEffort wise, then plus as the original 5xBodyweight against load and 4xBodyweight against

Picket Holdfasts:

(holdfast is old sailing term for immediate, rigid, iron strong, absolute 'bombpruf',unyielding anchor position and lashing/hold per anticipated loading).

US.mil Field Manual 5-125 is an excellent, bare bonz guide to many topics, including key anchoring(look for all these things to need a rigid 'ground' like electrical model, thus electrical ground schematic symbols in last pic above) connection to get power/light the rope with force as if wire!

US.mil Field Manual 5-125 should be required reading to expand mind out of only tree mindset, to then come back to trees now deeper in own powerband of understanding of rawest workings.

Manual shows pickets (page_4-3 to 4-8 )at 45 degrees, then the high to low ropes at 90 to stake high towards load, low on next stake further away, tightened, then Spanish Burton/tourniquet type further tightening between stakes/stake plates to iron rigid. Guide goes into deadman's and numbers before going to small crane and gin poles, very good imagination stretcher for what are the real, minimal basics to watch for those that really start with much less of nothing and do magic.

Perhaps about the only place to see this nifty utility grade clean, quick release: Speir page_2-13 but figure_2-17 in their numbering.. From it have done 1" pipes as rollers to get hot top thru doorway etc. Any jewels seen on this short journey, that have to come back to and true up focus again as read again once same silhouette is sighted in field.

.

edit fig_3-4 on page_3-5 is key model/reminder to me as also seen in ABoK

ABoK Lesson# 3267+/pg.533: Mousing a Hook

Look at carabiner as a fancy moused hook, with only 1 solid leg to one side

After all the gate's weakest link tends to be a thin steel axle pulled not lengthwise to it's strongest axis, but rather cross wise against it's weakest axis.

.

edit: absolute key(s)

pulley rolling lever is incremental additive of cos vals

rigid lever is multiplier of sine val

capstan frictions are compounding with cos+sine vals !

ALL displacements against space and/or force can be shown as cos/sine; even predict star movement and waveforms of wind, electric very accurately!!

Pulley and Capstan tools give us science of each extreme in the powerband shown

>>pulley is pulley theory + so much capstan

>>1 turn on capstan can likewise show capstan theory plus some pulley etc.

pulley and capstan are extremes, actuals in between inheriting some from each extreme border parent to the actual.